The Challenge

A facility producing small CO₂ bottles needed a filling solution that:

- Measured to 0.01 lb accuracy for precise fills

- Worked ergonomically for operators of different heights with bottles of different lengths

- Could be set up only when needed and stored away from the filling area when not in use

- Integrated safety interlocks to prevent overfilling or operator error

Their existing scales were designed for larger tanks, making them too coarse for the smaller bottles in this product line

The Solution

Peninsula Scale designed a mobile, ergonomic filling station with precision load cell technology and automated control.

Key Features:

- Hydraulic height-adjustable cart: Operators can set the fill neck to an optimal working height, reducing strain and improving safety.

- Custom scale mount: Supports bottles upright and handles hose weight without tipping.

- 25 lb NIST-certified test weight: Onsite verification of scale accuracy during shifts.

- Industrial-grade quick disconnect: Allows scale to be removed for storage when not in use.

Smart Controls for Automated Filling

We selected the Rinstrum R427 panel-mount controller, which includes a single-ingredient filling application—no expensive custom programming required.

Automation Benefits:

- Store multiple target weights and bottle sizes for fast changeovers

- Industrial push-button controls and labeled emergency stop for operator safety

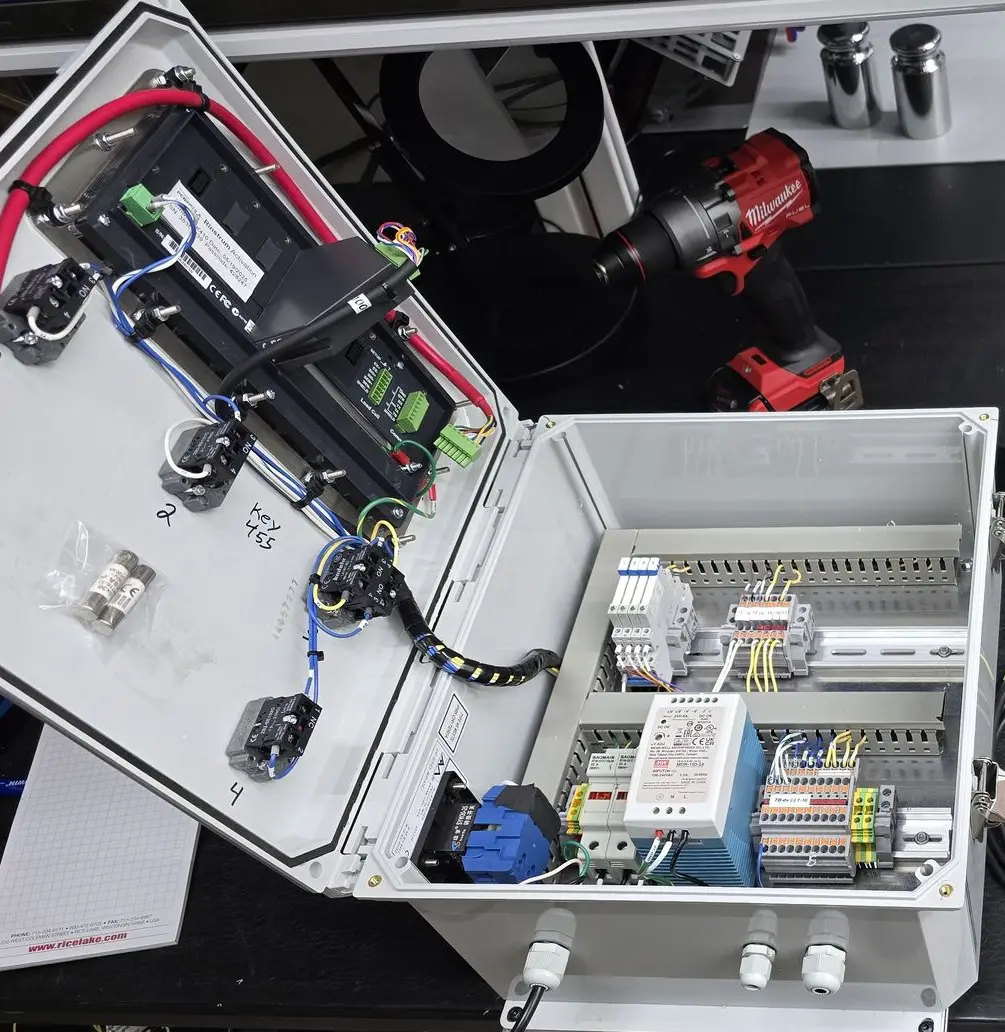

- Panel enclosure with integrated power supplies, relays, and wiring—built and tested in-house

- The outside of the enclosure, the button functionality was labelled using plastic button tags

- Solenoid-controlled industrial valve to handle CO₂ pressures and temperatures reliably

Installation, Training & Support

Our automation technicians handled:

- Onsite installation and calibration for full-capacity accuracy

- Operator training for start/stop procedures and changeovers

- Setup of dual-fill hose functionality for increased throughput

- Testing with customer’s bottles and CO₂ supply to ensure reliability

How It Works

- Operator places an empty bottle on the scale and presses Start.

- Scale automatically tares the bottle weight to zero.

- Solenoid valve opens and begins filling.

- Scale continuously monitors weight in real time.

- When the target weight is reached, the valve closes automatically.

- Operator disconnects the filled bottle and repeats.

This process ensures every bottle is filled within tolerance, prevents overfilling, and eliminates dependence on operator reaction time.

Why Partner with Peninsula Scale for Filling Automation

- Experience across industries: From gas cylinders to liquid and dry bulk packaging

- Turnkey solutions: Mechanical, electrical, and control integration in one package

- Scalable designs: For bottles, buckets, barrels, bags, or boxes

- Safety-first approach: Reducing operator risk while maximizing productivity

📞 Call (407) 391-1072 or email info@penmfg.com to schedule a free onsite assessment for your next automated filling project.

We’ll design a solution that improves accuracy, speed, and safety—while lowering labor costs and downtime on your next automation project.