Removing The Truck Scale

This customer had mined nearly all of the material from their original location and had purchased a new mining location about 10 miles away. They wanted to remove one of their existing truck scales from the original location and get it setup at the newly permitted location to speed up their truck weighing process.

We were able to assist the customer in safely removing the load sensors and wiring out of the truck scale deck and loading the scale deck onto a flat bed trailer. Challenges such as rusted and corroded hardware, sediment built up in conduits and anchor bolts that needed to be cut to remove the loadcell stands are fairly typical for this type of environment.

Preparing the Foundation

The new foundation utilized half of the old foundation from a previous truck scale that had been removed and scrapped long ago. There were old anchor bolts and welded tabs that would interfere with the new scale installation, so these were cut off and ground smooth to allow for proper clearance for the scale in the new foundation. This save some significant costs and lead time over pouring an entirely new foundation.

Some of the most common chronic issues with truck scale maintenance is improperly gapped scale checking systems and foundation measurements, taking a few minutes to do this now can save years of issues with rubbing and friction that causes inaccurate weights and additional service costs for truck scale owners & operators.

The customer needed to place their crane on some green concrete so they applied a layer of dirt to help distribute the load out on the crane to try to avoid cracking. We assisted the customer in aligning proper end wall gapping and wood blocks to set the scale modules in place.

Installing the Truck Scale

The customer was responsible for lifting the scale so their crane was positioned in place and the scale modules were carefully set into the new foundation with our team ensuring the scale put in the proper positioning within the foundation.

The loadcell stands, loadcells, wiring, conduit and junction boxes were all laid out on the scale deck. The stands were set into their proper locations and wedge anchors were drilled into the concrete to hold them in the proper position.

Grease was applied to the appropriate moving suspension pieces and "NeverSeize" compound was applied to all bolt threads to ensure hassle free maintenance in the future.

Wires were pulled through the scale deck and properly terminated at the junction box.

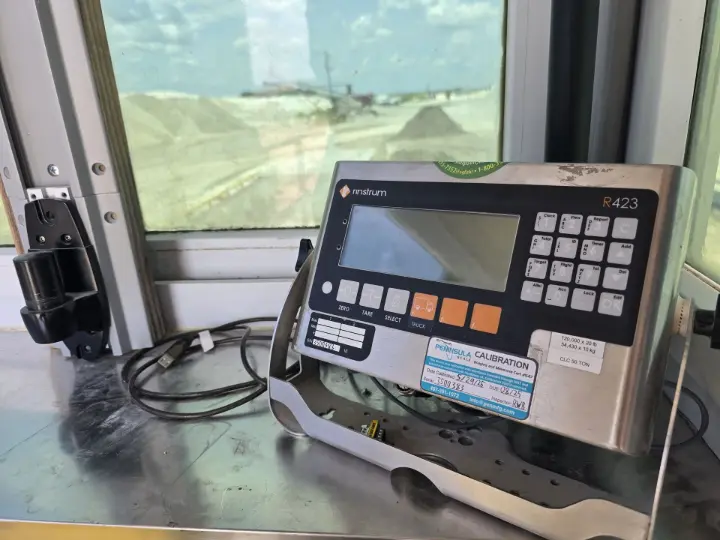

Calibration, Testing, and Placing in Service

Once the scale deck was in place, home run cable and ground wires were run up into the scale house. The new scale instrument was setup with data outputs to the PC software, large outdoor remote display and ticket printer.

The scale was calibrated with our motorized test cart and strain tested to proper capacities to place the scale back into service with the Florida Department of Agriculture Weights and Measures.

If you have an upcoming truck scale project, please give is a call (407-391-1072) or email (info@penmfg.com) and we would be happy to see how we might be able to make it go smoothly for you!